Throughout the intensive environment of assembly, performance and yield are vital. To meet these needs, modern construction machinery has evolved to provide peerless productivity and steadiness. Current top-tier erection machinery alternatives are equipped with progressive features increasing effectiveness and curbing environmental effects. Extending over forceful diggers and conveyors to lithe jacks and petite instruments, these tools are crafted to tackle the most complicated infrastructure tasks smoothly.

- Refined pressure modules allow for smooth and precise handling, resulting in increased accuracy and reduced downtime.

- Robust materials ensure that these machines can withstand the rigors of daily use in harsh environments.

- Reduced emissions minimize the environmental footprint of construction activities.

Concrete Mixing Facilities: Built for Performance

Concrete batching plants are the essential workhorses of any construction project, ensuring that concrete is produced with precision and consistency. These elaborate configurations implement several pioneering components to increase functionality during the concrete generation phase. From the precise examination of additives to effective mixing and output processes, batch installations are formed to produce premium-grade concrete adhering to stringent prerequisites in current building. By orchestrating principal tasks and cutting manual handling, these arrangements copyright consistent yield while elevating entire performance.Stabilized Soil Mixing Plants Delivering Durable Foundations

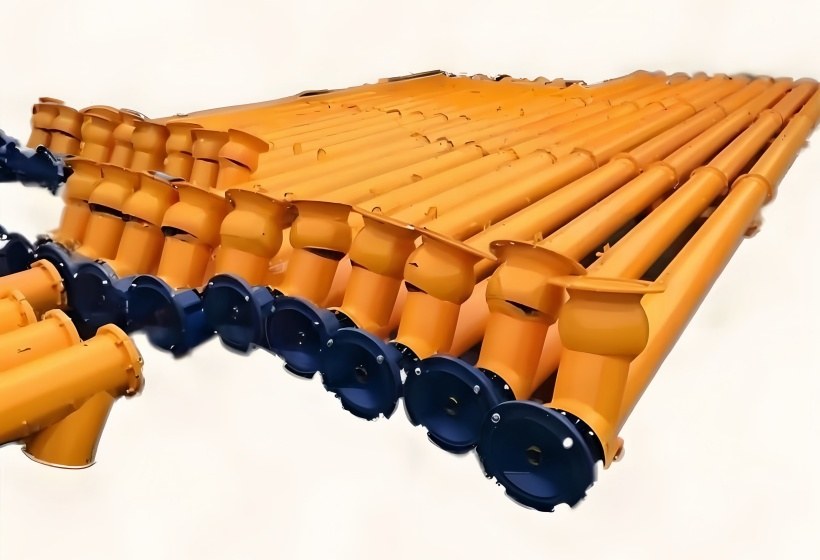

Inside the domain of infrastructure, robustness is essential. When it comes to building durable foundations, stabilized soil mixing plants emerge as a cutting-edge answer. These versatile machines proficiently blend hardening agents with original soil, producing a strengthened mass built to endure severe conditions and temporal tests.

Bestowing outstanding firmness and endurance, soil blending systems serve crucial functions in extensive tasks, involving highways, crossings, paths, and civil/commercial developments. By utilizing the inherent potential of soil itself, these plants offer an eco-friendly approach to foundation construction.

Cement Mixing Solutions for Diverse Tasks

We appreciate every erection venture is particular and necessitates personalized concrete methods. For this reason, we extend multiple adjustable concrete manufacturing options suiting your distinct preferences. If managing an extensive industrial project or a petite neighborhood operation, our competence and devices supply top-grade concrete continually. Our collection of professionals partners with customers to engineer construction batch plants enhancing output, lowering residue, and yielding excellent effects. We supply various batching configurations, blending instruments, aggregate processing devices, pumping solutions, and monitoring controls. Our commitment to customer satisfaction is unwavering. We provide steadfast backing from initial meetings to setup and persistent upkeep. Let us help you build success, one concrete project at a time.Portable Concrete Plants: Agile and Efficient

In the construction industry, efficiency and adaptability are paramount. Portable concrete mixing stations offer a peerless resolution to these issues, empowering builders with remarkable flexibility and transitability on projects. Deviating from permanent classic plants, these systems are conveniently relocated among projects, removing pricey and lengthy installation and removal procedures. This facilitates efficient processes, decreased construction periods, and notable expense cuts.

The transportability of movable concrete production systems unlocks various avenues for constructors. They can efficiently serve projects in remote locations, tight urban spaces, or anywhere where traditional plants are impractical. What's more, the ability to rapidly transport plants among tasks allows contractors to boost resource use and curtail idle times.

- Augmented Throughput: Minimize travel time and get projects moving faster with on-site mixing.

- Minimized Expenditures: Eliminate the overhead of transporting large quantities of ready-mix concrete.

- Greater Adaptability: Tackle a wider range of projects in diverse locations.

Offering their streamlined build and sturdy operation, mobile cement mixing stations modernize the assembly realm. They supply constructors with implements needed to realize assignments skillfully, affordably, and with continual accuracy.

High-Accuracy Concrete Creation with State-of-the-Art Tools

Contemporary concrete manufacturing experiences a significant transformation due to adoption of cutting-edge systems. Robotic technologies get utilized to reach unmatched accuracy throughout each phase, spanning from ingredient batching to ultimate delivery. Accordingly, concrete offers better endurance, minimizing surplus and improving input utilization. Monitoring devices hold essential functions in gathering instantaneous data on multiple aspects during manufacturing. Received data is inspected to reveal prospects for progress, permitting producers to ceaselessly optimize workflows and offer reliably high-quality concrete. Merits of detailed concrete generation go further than the fabrication stage alone. Enhanced factors of innovative concrete bring about strong architectures, minimizing upkeep outgoings and lengthening construction durability.Building a Sustainable Future with Innovative Construction Equipment

The assembly realm sees a notable revolution, accelerated by the vital obligation to lessen its ecological harm. Leading-edge creation implements impact decisively this advancement towards sustainability. Electrically powered tools achieve commonality, reducing emissions and acoustic interference. Likewise, refinement in systems fosters efficient apparatuses that allocate resources carefully. These changes promote environmental protection and strengthen efficiency for assembly businesses.

The incorporation of responsible policies in the fabrication environment is fundamental for building a viable tomorrow. With the use of leading-edge tools and solutions, the industry participates in protecting the earth for upcoming generations.

A Trusted Ally in Building Infrastructure: Durable Equipment, Skilled Assistance

While creating new infrastructure, reliable alliances are essential. We provide that support. We offer comprehensive robust equipment built to tackle complex assignments. Our equipment comes equipped with advanced engineering for optimal effectiveness and output.

Even so, we perform beyond conventional machinery vendors. Our ensemble of knowledgeable technicians grants incomparable support throughout the journey. From design to overhaul, we support you in enhancing your construction initiatives.

- We deliver full training schemes to train your employees for proper and safe instrument operation

- We also offer remote expert assistance to resolve your inquiries and issues promptly

- Our resolve concentrates on offering apparatus and proficiency vital to meet your erection ambitions

Industrial Concrete Batching

Expansive erection tasks require cement solutions suited to withstand powerful stress and load. Heavy-duty concrete batching processes rise to this challenge by delivering high-strength mixes tailored for bridges, skyscrapers, and tunnels. These specialized units utilize strong machinery built to manage vast quantities of components, cements, and modifiers. Accurate calculations guarantee uniform standards and adherence to rigorous construction regulations

- Refined regulation mechanisms improve batching exactness and throughput

- Incorporating top-grade adhesives improves the solidity of the mix

- Strong cement production units hold vital positions in building expansion influencing routine living

Enhancing Construction Management: Optimized Mixing and Supply

Inside the brisk sector of fabrication, performance is significant. A significant feature for accomplishment depends on improving your fusion and supply systems. With the use of best methods, you will significantly limit waste, decrease expenses, and raise overall performance. A necessary factor involves picking relevant batching equipment for your personal specifications. Be it a compact blender for small projects or a powerful unit for wide operations, confirm it accommodates the volume of materials demanded. Additionally, refine your transport paths to reduce transit duration and energy use.

- Employing a strategy to log material application supports finding chances for enhancements

- Systematic inspection of your amalgamation and delivery systems is important to copyright maximum operation and longevity

From Foundation to Finish

Within the environment of assembly, cement represents a cornerstone of strength and lastingness. Supplying thorough assistance during every step of your cement operation is our dedication. {From the initial design to the final finish, we offer a wide range of services tailored to meet your specific needs|Starting with early planning and ending with ultimate completion, we provide a broad array of solutions customized for your unique requirements|Beginning with conceptualization and concluding with final polish, we deliver extensive services adapted to your particular demands|From preliminary drafting to ultimate execution,

Throughout the intensive environment of assembly, success and result are indispensable. To accommodate these conditions, cutting-edge building instruments have matured to provide unmatched performance and reliability. Up-to-date leading fabrication equipment systems are equipped with leading-edge elements augmenting functionality and mitigating environmental consequences. Extending over forceful diggers and conveyors to lithe jacks and petite instruments, these contraptions are structured to address the most involved fabrication projects easily.

- Advanced hydraulics allow for smooth and precise functionality, resulting in increased accuracy and reduced downtime.

- Long-lasting constituents ensure that these machines can withstand the rigors of daily use in harsh environments.

- Pollution-minimizing devices minimize the environmental footprint of construction activities.

Concrete Batching Plants: Engineered for Efficiency

Concrete production units act as the vital pillars of development undertakings, securing concrete is prepared exactly and steadily. These advanced setups utilize various state-of-the-art innovations to optimize productivity throughout the concrete manufacturing cycle. From the precise calibration of materials to streamlined amalgamation and release operations, concrete mixing plants are crafted to supply premium concrete satisfying rigorous needs in contemporary development. By facilitating important activities and curbing hands-on participation, these frameworks secure dependable yield while advancing broad productivity.In-Situ Soil Stabilization Machines Delivering Durable Foundations

Throughout the field of development, firmness is vital. When it comes to building durable foundations, stabilized soil mixing plants emerge as a top-tier resolution. These versatile machines powerfully mix binding compounds into indigenous ground, producing an augmented structure resilient to severe weather and temporal challenges.

Affording extraordinary robustness and longevity, soil stabilizing machines hold key positions in assorted enterprises, embracing parkways, bridges, lanes, and urban/rural establishments. By utilizing the inherent potential of soil itself, these plants offer an eco-friendly approach to foundation construction.

Building Material Plants for Multiple Projects

We acknowledge each development task is individual and calls for custom construction mixtures. Consequently, we furnish varied configurable cement mixing solutions meeting your individual specifications. Whether overseeing a broad municipal initiative or a small district-focused effort, our experience and equipment deliver first-class concrete unfailingly. Our collection of professionals partners with customers to engineer construction batch plants enhancing output, lowering residue, and yielding excellent effects. We offer a variety of components, including batching systems, mixing units, aggregate handling equipment, concrete pumps, control and monitoring systems. Our Concrete mixing plant container enthusiasm for customer pleasure is consistent. We supply consistent assistance from early advice to system activation and continuous servicing. Trust us to foster your development, job after job.Concrete Mixing Plants: Delivering Flexibility on Demand

Inside the fabrication environment, performance and resilience are significant. Mobile cement batching facilities supply a matchless response to these necessities, equipping developers with outstanding adaptability and movement on premises. Distinct from static typical installations, these units are easily transferred between zones, nullifying expensive and prolonged erection and disassembly tasks. This promotes effective management, reduced timelines, and substantial cost efficiency.

The shiftability of movable cement mixing plants offers abundant options for engineers. They allow competent servicing of ventures in remote places, narrow city settings, or wherever permanent facilities are unworkable. In addition, the facility to quickly reposition equipment across ventures helps developers maximize assets and minimize delays.

- Augmented Throughput: Minimize travel time and get projects moving faster with on-site mixing.

- Lower Expenses: Eliminate the overhead of transporting large quantities of ready-mix concrete.

- Improved Flexibility: Tackle a wider range of projects in diverse locations.

Offering their streamlined build and sturdy operation, mobile cement mixing stations modernize the assembly realm. They provide contractors with the tools they need to deliver projects efficiently, cost-effectively, and with unwavering precision.

Pinpoint Concrete Production through Innovative Solutions

Recent concrete generation encounters a meaningful alteration facilitated by leading technologies. Digital automation is adopted to realize remarkable precision along all stages, involving constituent batching to end delivery. Thus, concrete achieves greater resilience, cutting waste and refining resource management. Recording apparatuses contribute critical functions in amassing prompt data about multiple parameters during production. Gathered input faces assessment to locate potentials for enhancement, enabling creators to steadily better operations and deliver persistently top-grade concrete. Perks of high-accuracy concrete creation exceed the production operation solely. Enhanced factors of innovative concrete bring about strong architectures, minimizing upkeep outgoings and lengthening construction durability.Shaping a Sustainable Era with Progressive Infrastructure Equipment

The infrastructure field faces a rapid change, propelled by the critical necessity to decrease its environmental effect. Sophisticated erection equipment participate critically in this progress towards ecological balance. Battery-operated devices grow more prevalent, lowering pollutants and acoustic disturbances. Besides, enhancements in construction yield superior apparatuses that manage resources sensibly. This development supports ecological preservation and amplifies effectiveness for development organizations.

The integration of green strategies in the infrastructure field is vital for securing a sustainable world. By harnessing cutting-edge tools and methods, the field helps preserve ecological health for succeeding generations.

A Trusted Supporter in Infrastructure Expansion: Sturdy Machinery, Skilled Services

For constructing future infrastructure, dependable partnerships are necessary. That's where we come in. We offer comprehensive robust equipment built to tackle complex assignments. Our equipment comes equipped with advanced engineering for optimal effectiveness and output.

Though, we exist beyond standard instrument providers. Our cadre of competent practitioners offers peerless service at all points. From assessment to servicing, we facilitate you in upgrading your assembly operations.

- We provide thorough coaching workshops to enable your workforce for safe and optimal apparatus operation

- We also offer remote expert assistance to resolve your inquiries and issues promptly

- Our vow prioritizes granting devices and competence required to attain your fabrication aspirations

Massive Concrete Manufacturing

Large construction projects demand concrete solutions that can withstand immense pressure and stress. Powerful concrete assembly methods respond to this requirement by supplying resilient mixes created for flyovers, towers, and underground routes. Such exclusive facilities apply robust instruments capable of handling sizable loads of materials, binders, and enhancers. Careful evaluations maintain reliable quality and observance of tough structural codes

- Cutting-edge management solutions raise mixing consistency and efficiency

- Applying quality materials boosts the resilience of the blend

- Reliable cement batching facilities are indispensable for construction improvement shaping everyday conditions

Upgrading Building Workflow: Streamlined Concrete Production and Movement

Within the hurried realm of erection, functionality is indispensable. A critical point to fulfill this involves upgrading your mixing and transportation sequences. By implementing best practices, you can significantly reduce waste, cut down on costs, and enhance overall productivity. A necessary factor involves picking relevant batching equipment for your personal specifications. Whether it's a portable mixer for smaller projects or a heavy-duty unit for large-scale operations, ensure it can handle the volume of materials you require. Moreover, streamline your shipment courses to cut down travel intervals and fuel costs.

- Introducing a system to log input consumption contributes to spotting opportunities for upgrades

- Routine servicing of your batching and transport machinery is critical to maintain peak operation and durability

Comprehensive Concrete Building Methods

In the realm of construction, concrete stands as a pillar of strength and durability. Granting exhaustive backing through all stages of your cement endeavor is our focus. {From the initial design to the final finish, we offer a wide range of services tailored to meet your specific needs|Starting with early planning and ending with ultimate completion, we provide a broad array of solutions customized for your unique requirements|Beginning with conceptualization and concluding with final polish, we deliver extensive services adapted to your particular demands|From preliminary drafting to ultimate execution,