In the domain of industrial operations, safeguarding the wholeness and operation of lines is required. Buildup of residue within passages can notably restrict fluid movement, lessen production excellence, and increase upkeep expenses. To confront these difficulties, tube cleansing methods have sprung up as preeminently adept resolutions for efficient pipeline sanitation. A gadget, commonly a cylindrical gizmo, is pushed through the pipeline, productively removing contaminations and securing optimal performance

Duct washing methods yield numerous positive points. They are adjustable, equipped for sanitizing pipes of heterogeneous sizes and ingredients. Furthermore, they are efficient, fulfilling the operation in a moderately rapid duration. By curtailing downtime and improving pipeline output, pipeline cleaning systems foster budget cuts and boosted operational yield

Sanitary Pigging Solutions:

Securing pipeline pristineness is vital for affirming product safety and caliber of relayed outputs. Sanitary pigging solutions supply a solid way to accomplish this purpose. Pigs, dedicated implements, are introduced into pipelines to decontaminate by displacing residues and pollutants

- Countless varieties of sanitary pigs are obtainable, each designed for dedicated cleaning purposes.

- These pigs are created from substances that adhere to stringent pure standards.

- Scheduled sanitary pigging exercises assist stopping product infection, maintain pipeline resilience, and enhance general productivity.

Modern Pigging Techniques for Top Functionality

Throughout the sphere of line support, sophisticated pigging approaches have become a critical tool for ensuring best efficiency and defense. These revolutionary systems exploit clever formulations and aspects to adeptly disinfect, analyze, and secure channels from corrosion. From advanced pigs provided with live observation systems to tailored pigging instruments created for intricate tasks, progression in this area is perpetually broadening frontiers. By using these enhancements, administrators can markedly improve pipeline integrity, lower downtime, and heighten operational capability.

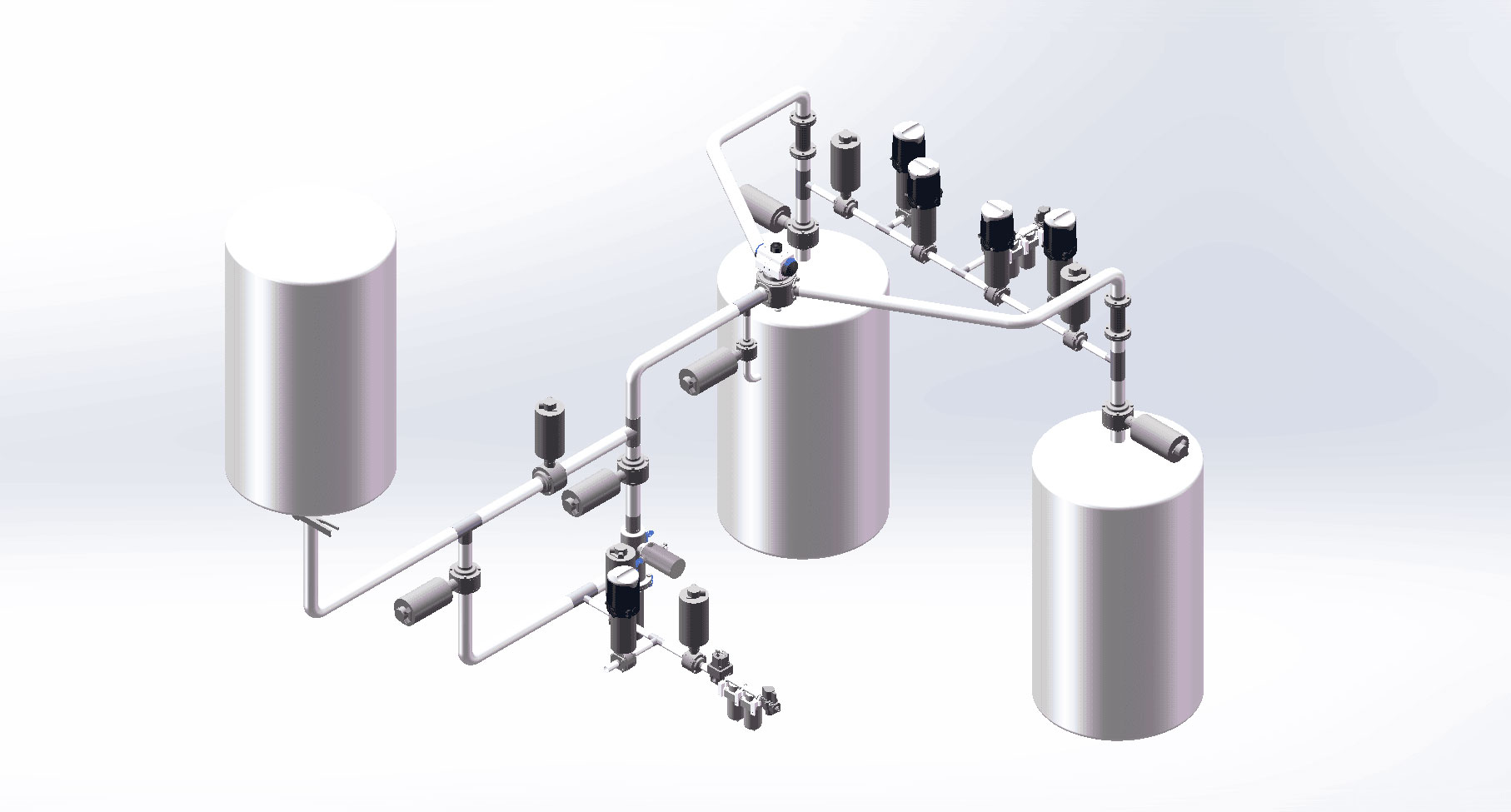

Extensive Pigging Framework Planning and Assembly

The systematic pigging system integrates a important framework for pipeline preservation. This system involves the integration of designed instruments called pigs, which travel through tubes to flush, check, and conserve their strength. The architecture values considerations such as duct diameter, ingredient, pig class, and operational demands. A intelligently crafted system delivers effective pigging functions while reducing downtime and potential damages. Installation rules require careful designing, skilled specialists, and strict adherence to safety guidelines to confirm a safe and fruitful conclusion

Mechanical Pigging Instruments for Broad Employments

Industrial pigging instruments are vital devices used across a ample range of industries. These apparatus enable sound and efficient purging, inspection, and care of conduits and other pipe-like forms. Pigging requires sending dedicated tools known as pigs through pipes to complete multiple functions. Classic types of industrial pigging tools contain cleaning pigs, inspection pigs, and distribution pigs. Cleaning pigs are made to wipe off debris, build-up, and unwanted substances from pipelines. Inspection pigs are loaded with apparatus that collect information about the status of pipe bases. Transport pigs are mobilized to move substances through pipelines. The use of industrial pigging products grants numerous benefits, such as reduced downtime, boosted pipeline strength, and heightened operational capacity. These instruments are commonly used in areas such as oil and gas, water treatment, chemical production, and food manufacturing.Pipeline Pigging: An Exhaustive Guide

Pipeline pigging is an critical procedure used within the oil and gas realm to survey pipelines. This crucial task requires placing engineered apparatuses, dubbed pigs, into the pipeline. Pigs are constructed to traverse the stretch of the pipeline, completing various assignments.

Some sorts of pigs are ready, each built for a designated objective. Common applications of pipeline pigging include evaluation for defects, decontamination, and pipeline rehabilitation.

- Gains of Pipeline Pigging

- Consequences on Operational Efficiency

- Classes of Pipeline Pigs

Trusted Sanitation by means of Pigging Methods

Pigging mechanisms supply a proven answer for achieving sanitation inside ducts. These technologies make use of tailored devices that move through the pipeline network, efficiently eradicating impurities. The practice is especially effective for domains that call for rigorous cleanliness standards. Pigging systems supply a reasonably priced and speedy approach for purifying systems, reducing the exposure of spoilage.

Opting for Pigging Tools for Specific Expectations

Pigging machinery performs a important role in best pipeline work. When opting for pigging tools, it is paramount to consider the specialized conditions of your application. This encompasses reviewing factors such as pipeline breadth, flow capacity, product kind, and restoration demands.

Various pigging versions are present, each designed for distinct objectives. Such as, some pigs are meant for assessment, while others are deployed for eliminating pollutants or segmenting product groups.

What's more, pigging apparatus items should be harmonious with the transported medium.

It is frequently beneficial to collaborate with a authority in pigging solutions to secure that you elect the most proper tool for your distinct expectations.

Pipeline Cleaning Arrangements - A Efficiency-Endowed Approach

Cleaning frameworks yield a diverse spectrum of assets for fields focused on pipelines. By successfully cleaning and monitoring channel interiors, pigging systems maximize operational productivity and alleviate maintenance expenses.

A main positive of pigging systems is their skill to eliminate fouling such as dirt, debris, and decay products. This scheduled sanitation affirms frictionless pipeline passage and reduces costly downtime.

Additionally, pigging systems can be used to check the soundness of pipelines, detecting likely anomalies before they expand into major difficulties. This forward-looking procedure boosts to prolong durability of pipelines and minimize overall maintenance budgets.

Preserving Hygiene in Pigging Activities

Pig farming practices fundamentally trust appropriate hygiene guidelines to restrain the transmission of diseases. Adopting rigorous hygiene measures maintains a sound habitat for pigs, thus generates optimal health outcomes and functionality.

Detailed cleaning and disinfection of premises is vital to control the presence of harmful pathogens. Adequate waste management furthermore serves a major part in maintaining hygiene.

Furthermore, pigging systems {workers